Page 327 - CATALOG

P. 327

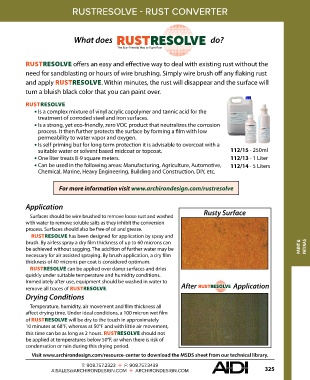

RUSTRESOLVE - RUST CONVERTER

What does do?

RUSTRESOLVE offers an easy and effective way to deal with existing rust without the

need for sandblasting or hours of wire brushing. Simply wire brush off any flaking rust

and apply RUSTRESOLVE. Within minutes, the rust will disappear and the surface will

turn a bluish black color that you can paint over.

RUSTRESOLVE

• Is a complex mixture of vinyl acrylic copolymer and tannic acid for the

treatment of corroded steel and iron surfaces.

• Is a strong, yet eco-friendly, zero VOC product that neutralizes the corrosion

process. It then further protects the surface by forming a film with low

permeability to water vapor and oxygen.

• Is self priming but for long term protection it is advisable to overcoat with a

suitable water or solvent based midcoat or topcoat. 112/15 - 250ml

• One liter treats 8-9 square meters. 112/13 - 1 Liter

• Can be used in the following areas: Manufacturing, Agriculture, Automotive, 112/14 - 5 Liters

Chemical, Marine, Heavy Engineering, Building and Construction, DIY, etc.

For more information visit www.archirondesign.com/rustresolve

Application

Surfaces should be wire brushed to remove loose rust and washed Rusty Surface

with water to remove soluble salts as they inhibit the conversion

process. Surfaces should also be free of oil and grease.

RUSTRESOLVE has been designed for application by spray and

brush. By airless spray a dry film thickness of up to 60 microns can

be achieved without sagging. The addition of further water may be PAINT & PATINAS

necessary for air assisted spraying. By brush application, a dry film

thickness of 40 microns per coat is considered optimum.

RUSTRESOLVE can be applied over damp surfaces and dries

quickly under suitable temperature and humidity conditions.

Immediately after use, equipment should be washed in water to

remove all traces of RUSTRESOLVE. After Application

Drying Conditions

Temperature, humidity, air movement and film thickness all

affect drying time. Under ideal conditions, a 100 micron wet film

of RUSTRESOLVE will be dry to the touch in approximately

10 minutes at 68°F, whereas at 50°F and with little air movement,

this time can be as long as 2 hours. RUSTRESOLVE should not

be applied at temperatures below 50°F, or when there is risk of

condensation or rain during this drying period.

Visit www.archirondesign.com/resource-center to download the MSDS sheet from our technical library.

T: 908.757.2323 ✛ F: 908.757.3439

AISALES@ARCHIRONDESIGN.COM ✛ ARCHIRONDESIGN.COM 325