Page 241 - Catalog

P. 241

PANELGRIP 2 GLASS RAILING SYSTEM

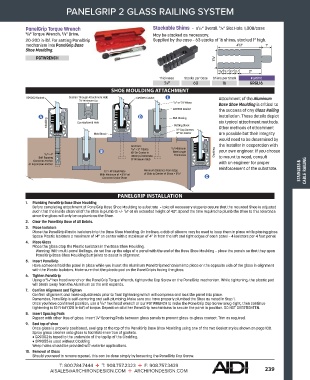

PanelGrip Torque Wrench Stackable Shims - 5 /8” Overall. /8” Slot Hole. 1,008/case

1

5

3

3 /8" Torque Wrench, /8" Drive, May be stacked as necessary.

20-200 in-lbf. For setting PanelGrip Supplied by the case – 63 stacks of 16 shims, stacked 1” high.

mechanism into PanelGrip Base

Shoe Moulding.

PGTWRENCH

Thickness Stacks per Case Shims per Stack PLASTIC

1 /16" 63 16 GRGL16

SHOE MOULDING ATTACHMENT

Attachment of the Aluminum

Base Shoe Moulding is critical to

the success of any Glass Railing

installation. These details depict

six typical attachment methods.

Other methods of attachment

are possible but their integrity

would need to be determined by

the installer in cooperation with

your own engineer. If you choose

to mount to wood, consult

STAINLESS & CABLE RAILING

with an engineer for proper

reinforcement of the substrate.

PANELGRIP INSTALLATION

1. Plumbing PanelGrip Base Shoe Moulding

Before completing attachment of PanelGrip Base Shoe Moulding to substrate – take all necessary steps to assure that the mounted Shoe is adjusted

such that the inside channel of the Shoe is plumb to +/- /8" at an extended height of 42". Spend the time required to plumb the Shoe to this tolerance

1

since the glass will only be as plumb as the Shoe.

2. Clear the PanelGrip Base of All Debris.

3. Place Isolators

Place the PanelGrip Plastic Isolators into the Base Shoe Moulding. On inclines, a dab of silicone may be used to keep them in place while placing glass.

Space Plastic Isolators a maximum of 14" on center with a maximum of 4" in from the left and right edges of each panel – 4 isolators per 4 foot panel.

4. Place Glass

Place the glass atop the Plastic Isolators in the Base Shoe Moulding.

Warning: With multi-panel Railings, do not line up the edge of a panel with the end of the Base Shoe Moulding – place the panels so that they span

PanelGrip Base Shoe Moulding butt joints to assist in alignment.

5. Insert PanelGrip

Have someone hold the panel in place while you insert the Aluminum PanelGrip mechanism into place on the opposite side of the glass in alignment

with the Plastic Isolators. Make sure that the plastic pad on the PanelGrip is facing the glass.

6. Tighten PanelGrip

Using a /16" hex head wrench or the PanelGrip Torque Wrench, tighten the Cap Screw on the PanelGrip mechanism. While tightening, the plastic pad

3

will break away from the Aluminum as the unit expands.

7. Confirm Alignment and Tighten

Confirm alignment and make adjustments prior to final tightening which will compress and lock the panel into place.

Remember, PanelGrip is self-centering and self-plumbing. Make sure you have properly plumbed the Shoe as noted in Step 1.

Once you have confirmed position, use a /16" hex head wrench or our PGTWRENCH to make the PanelGrip Cap Screw snug-tight, then continue

3

tightening to 10 ft-lbf (120 in-lbf) of torque. Repeat on all other PanelGrip mechanisms to secure the panel in position. DO NOT OVERTIGHTEN.

8. Insert Spacing Pads

1

Repeat with other lites of glass. Insert /4" Spacing Pads between glass panels to prevent glass-to-glass contact. Trim as required.

9. Seal top of shoe

Once glass is properly positioned, seal gap at the top of the PanelGrip Base Shoe Moulding using one of the two Gasket styles shown on page 108.

Spray glass cleaner onto glass to facilitate insertion of gaskets.

• GR9302 is taped to the underside of the top lip of the Cladding.

• GR9355 is used without Cladding

Weep holes should be provided with exterior applications.

10. Removal of Glass

Should you need to remove a panel, this can be done simply by loosening the PanelGrip Cap Screw.

T: 800.784.7444 T: 908.757.2323 F: 908.757.3439

AISALES@ARCHIRONDESIGN.COM ARCHIRONDESIGN.COM 239