|

A

Saddle Lock for the Lathemaster 9x30 Lathe |

This page describes a Vikki

Ford-style Saddle Lock (or Carriage Lock if you prefer) for the lathe.

I chose to do this project next for several reasons. First, I was really

tired of digging out my little Allen wrench to engage the stock saddle

lock. You have to clean out the chips to get at it, half the time it's

underneath the top slide dial, and in general it seems Mickey Mouse. I

am a big believer in engaging the saddle lock to increase rigidity for

facing and other operations. Second, I really like the look of Vikki Ford's

design compared to a lot of others I have seen cruising the web. It has

a very finished and well designed look about it. The pivoting gripper

just seems like it will work better and more smoothly than trying to drive

a gripper up and down on a thread and guide pin. I'm not sure I'll achieve

that total aesthetic, but we will see. Lastly, I wanted to experiment

with milling on the lathe. Vikki's design requires a slot to be milled

in one end of some rectangular stock. I do not have a milling attachment

for my lathe (yet), but somewhere I noticed a fellow was using his Quick

Change Toolholders as little milling fixtures. So, I ordered some end

mills from an eBay seller and set to work on aluminum, which will be another

thing I'm fooling with for the first time.

|

Part

1: Milling the Slot |

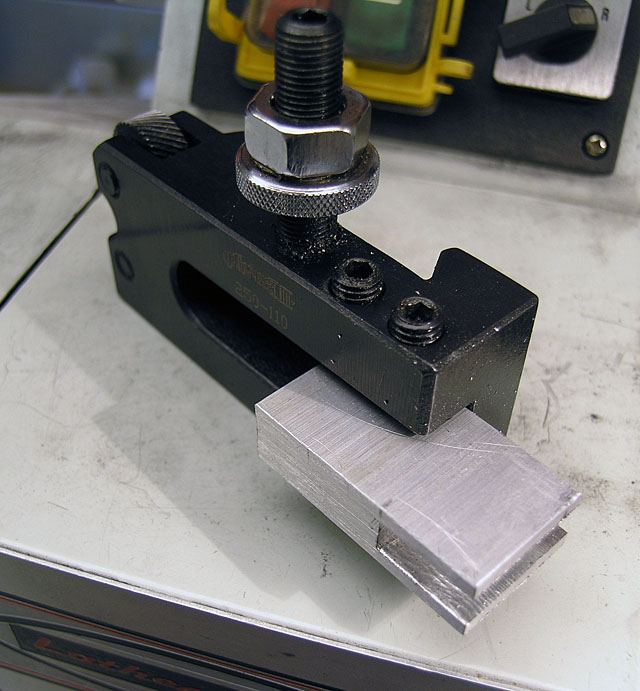

I cut myself a suitable

rectangle of aluminum with the horizontal bandsaw, chucked it up flat

in the 4-jaw, and then proceeded to make facing cuts until it was 0.500"

thick, at which point it fits into my Quick

Change Toolholder slots very nicely. Transfering the aluminum piece

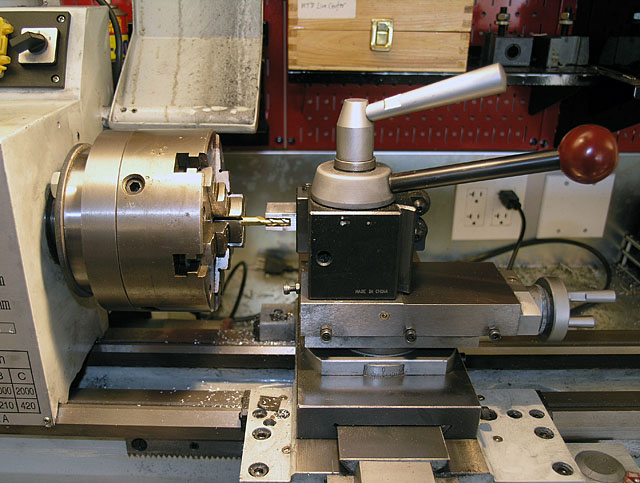

to the toolholder, I stuck a 1/4" endmill into my Buck

6-jaw Chuck. A 6-jaw has a better grip than a 3-jaw, so I reasoned

it would do a better job holding the end mill. Besides all that, it is

my favorite chuck so I never miss an opportunity to put it to use. I set

things up just as you would for facing, except that the work will be moving

into a whirling cutter instead of moving a cutter into the whirling work.

Try saying that 3 times fast!

Use a Quick Change Toolholder for Milling...

All in all, the milling

process worked out very well. It was entirely straightforward, and though

I was running the spindle at a pretty good clip, I detected no noticeable

chatter or other ill effects. I love my Lathemaster lathe! I was able

to make cuts on the order of 0.025" or even 0.030" with no problems.

As I was comfortable taking that much on each pass, I did not push things

any further. It is possible the lathe would take even deeper cuts, I just

didn't try.

The End Mill Goes In The Chuck...

|

Part

2: Drill the Holes |

We need to drill 3 holes.

There is a hole for the pivot on the gripper that runs side to side. Then

there are two vertical holes. First is the hole for the threaded bolt

that will press down on the gripper pivoting it up to engage the underside

of the ways. This hole will need to be tapped. Second is the mounting

hole for the bracket that holds the carriage lock from above. The mounting

hole must also be tapped.

|

Part

3: Make the Gripper and Pivot Pin |

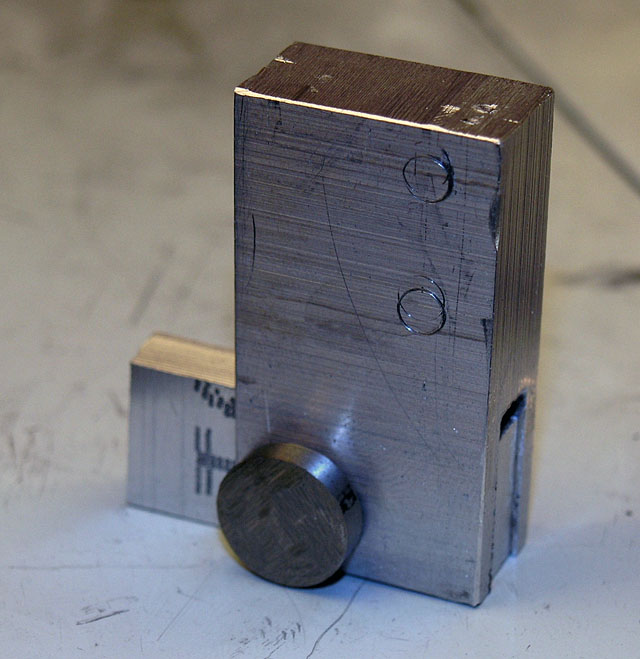

The Gripper is just a rectangle

of aluminum cut to appropriate size. You will need to drill a hole through

it for the pivot as well. I don't really trust threads in aluminum, so

I use a nut that's concealed between the lathe and the carriage lock to

secure the pin that the gripper pivots on. If you make the body of the

carriage lock from steel, you can thread the steel and potentially avoid

this. One thing to consider is that since we are only able to hold 1/2"

thick items in our "milling vice", you've only got an 1/8"

for threads. You may well prefer my method even for steel rather than

get by on so few threads.

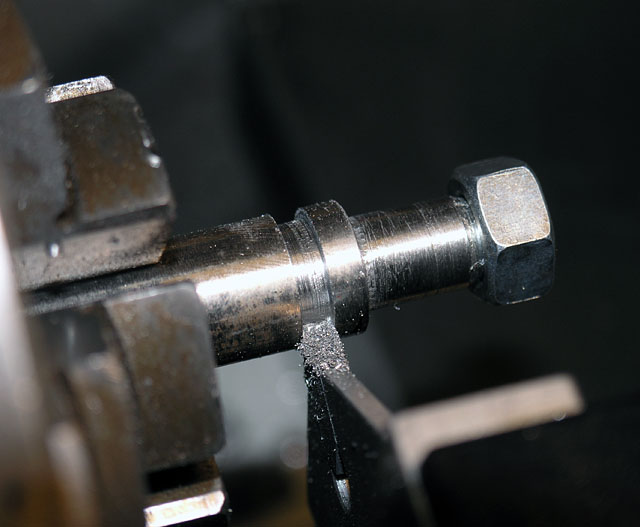

Preparing to Thread The Pivot Pin With Tailstock

Die Holder...

For the gripper's pivot

pin, I turned a little bolt with a shoulder and threaded the end, just

like Vikki Ford. I used stainless steel for the purpose. The pin has a

0.500" head, 0.350" pivot shoulder, and then the threads are

a bit smaller to clear the holes.

Part Off When Done Threading...

Trial Fitting the Gripper to the Lock Body With

Pivot Pin. Lots of Tool Marks to Clean Up!

|

Part

4: Make the Bracket |

The Saddle Lock Bracket

is another rectangle of aluminum cut to appropriate size. You will need

to drill three holes through it. One matches up to the bolt on the lathe,

one is for the bolt that holds the saddle lock (this time I did tap the

aluminum, so go easy on torquing that bolt!).

|

Part

5: Make the Handle |

For the handle I wanted

to match the style of the other handles on the lathe rather than producing

a ball handle or just a plain Tommy Bar. These handles are just tapered

cylinders. I made mine out of a piece of square steel stock and pressed

and Loctited it onto the top of the Allen head bolt I use to engage the

gripper.

|

Part

6: Install and Enjoy |

Bolt the whole thing together

on the lathe and try it out.

Back to Lathe Central...