|

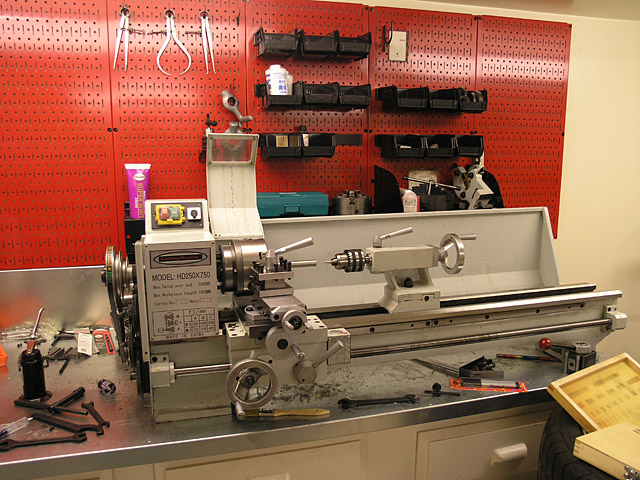

Lathemaster

9x30 First Chips! |

This page provides a bit

of early history of my lathe: how I chose it, and some shots of the first

chips I ever took with it.

The real thing, eh? Feelthy garage, I will organize

it later!

The heart of any machine

shop is the lathe, and this is also the first tool to learn on. Thus,

I purchased a lathe before I got to a mill and learned to use it first.

These 9 x 20 lathes are a great value compared to a larger capacity model,

easy to use, and there are tons of good modifications discussed on the

web. There are a lot of different variations on the basic 9x20 lathe.

The one I'm choosing is by Lathemaster,

who have a reputation for nicer machines than the average Asian models.

They're still made in China, but they are a more solid, quality control

is better, and sometimes they have more features. In this case, I have

a little more capacity between centers.

I push my lathe pretty hard,

as I like to use carbide insert cutters

which means cutting at pretty high speeds. I have found the Lathemaster

will stand up to it. All the others I read about need a 4-bolt compound

clamp and various other modifications before you can really start to use

the lathe in earnest. That is not the case here. This lathe works out

of the box very very well. I'm sure there are many mods I could make to

tighten up tolerances and add features, but I was very pleased with my

initial experiences after reading about other Asian

machines on the web.

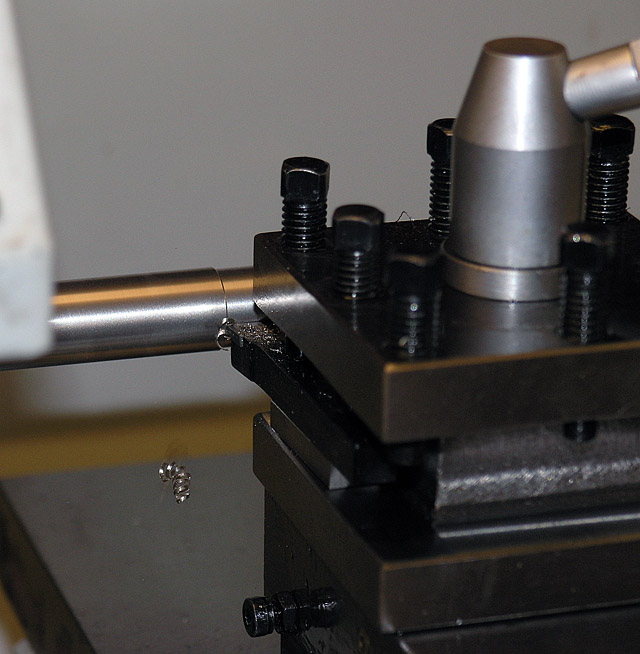

Making chips on the first day!

None of these machines is

really "finished" when compared to Western machines like a Hardinge.

So, amateur machinists modify them in a

variety of ways to make them better. Ultimately, you could even convert

one to CNC, but I'm not sure it's as advantageous for a lathe as it is

for the mill.

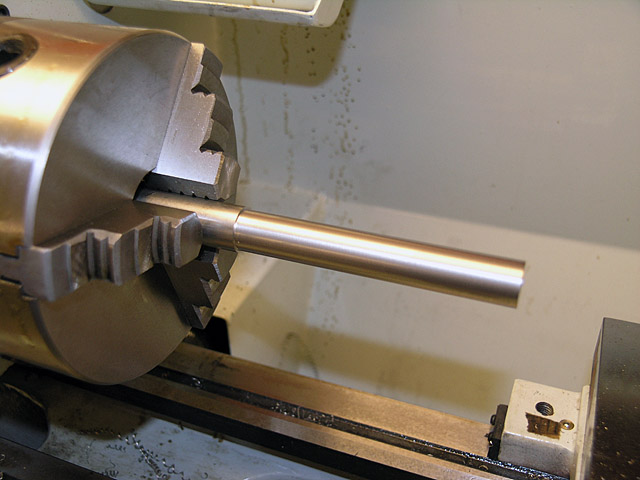

Converting a shiny lump of metal to a smaller, still

shiny lump. Nice surface finish, eh?

|

Cleanup |

The good news is that

the Lathemaster 9x20 is pretty

close to ready out of the box and you can begin taking cuts after cleaning

the cosmolene-like packing grease off the machine. Plan on spending an

afternoon taking things apart, cleaning them with kerosene, oiling them

(see the tip below on using chainsaw oil), and then putting them back

together. The only tools I had were a tin mug holding the kerosene, a

1" chip brush (you need a bunch of these anyway), lots of paper towels,

and an oilcan full of chainsaw oil. I read about some of the major work

that has to be done to other lathes, the very least of which is removing

burrs and replacing stuff that just flat doesn't work and I'm glad I spent

a bit more on Lathemaster. While

I'm on the subject, let me point out two things. First, if you've spent

any time on this site at all you'll know I have no affiliation with Lathemaster,

I just like their products. Second, I bought this lathe right after hurricane

Katrina had struck New Orleans, Lathemaster is very nearby in Baton Rouge,

and I still got great service and a great lathe!

Tip: You

can buy a container of expensive hard to find product called "Way

Oil" to oil your ways or you can buy chainsaw oil (chain bar oil).

This is also the proper oil for headstock bearings. This was confirmed

by Shell Oil technical help line that the two products are identical.

Here is what I took apart:

1) Tailstock: Remove tailstock

from lathe bed. Remove ram from tailstock (just extend it with the handwheel

until it comes off the screw and pull it out.

2) Turret-style Toolholder:

Unscrew the locking lever from the top and pull it off the compound. Wash

thoroughly in kerosene and apply rust preventative. I just used the oil

I had, wiping it down with a paper towel to leave a thin coating.

3) Compound

Slide: Remove from the cross slide by extending the screw until the slide

comes off the end. Be careful not to drop the gib (the little piece of

metal wedged into the dovetail). Clean with kerosene brush and oil.

4) Ways and

Leadscrew: Take your kerosene brush to these until they're clean and then

oil. Run the carriage from one end to the other and clean all the way.

Make sure the carriage is running smoothly across the ways on the rack

and pinion.

Note: Some

would continue by disassembling all the way to the carriage and apron.

This was a bridge too far for me. I oiled it and made sure it ran smoothly

and then moved on. You could probably at least remove the cross slide

as an intermediate step. Again, I got in a hurry to play!

5) Reassemble

the pieces you've removed back onto the lathe.

6) Next, I

lubricated the gear train using some white lithium grease. As they used

to say, "a little dab'll do ya."

7) Run around

all the little oil ports (there are many on this machine!) that you haven't

already hit and give a little squirt of oil.

8) I started

up the machine and let the leadscrew traverse the carriage from far right

all the way left, giving it an occassional oil squirt to make sure things

got a good coat of oil. I think I may have stopped the machine twice to

add another dab of lithium grease to the gear train. Be very careful--those

gears on my lathe are hardened metal and would grind a finger to pulp

if you get it caught in there.

9) Lastly I

cleaned up my chucks. I probably should have taken the jaws out, but I

settled for kerosene on the outside followed by a good oiling. I was anxious

to make some chips!

I love my little magnetic halogen lamp for the lathe!

(It came from eBay seller 800Watt)

Back to Lathe Home...