|

Want to be a better CNC'er? Get our weekly newsletter plus a package of greatest hits, special tips, and more, all for free. I'm Ready to Be a Better CNC'er, Hook Me Up! |

Machinery Dollies

WARNING: Moving heavy items is extremely dangerous. I don't recommend it and I don't know what I'm doing myself in this area. You should hire qualified professionals to move these items. You are on your own if you decide to do something similar as I am in no way claiming to know how to do it safely!

It seems like every time I order a piece of machinery from somewhere I go through torture to get it up to my shop. Invariably it arrives on a truck that's too large to go up my driveway, and after much heated discussion I wind up with a choice between shipping it back or figuring out how to get it up the driveway and into the garage myself. I could hire riggers to do the work each time, but some of this machinery is just not that big that I shouldn't be able to move it. It's all a question of having the right equipment to "git 'er done". I came across a couple of useful ideas in my travels. The first was a set of machinery dollies one fellow had made for himself that seemed hugely uesful:

Moving in a Shaper...

I like the combination toe jack and dolly arrangement. I came across a commercial product called a Rol-A-Lift that seemed equally as ideal:

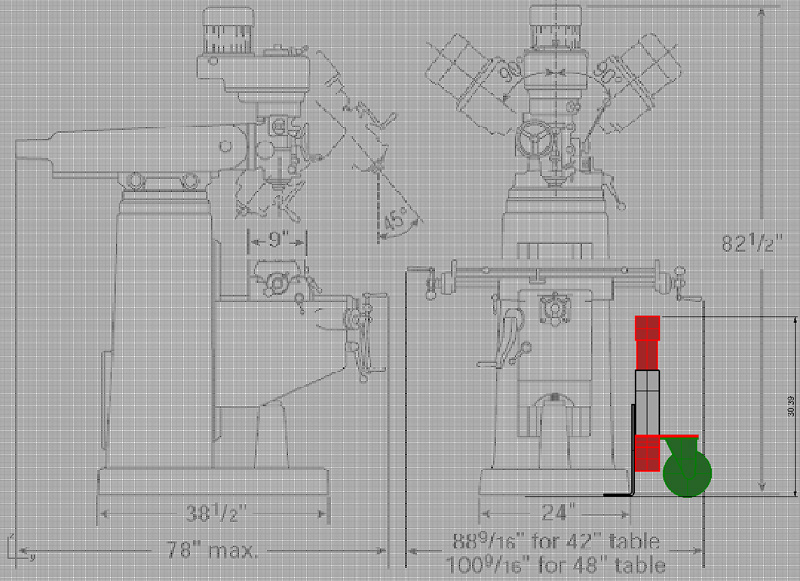

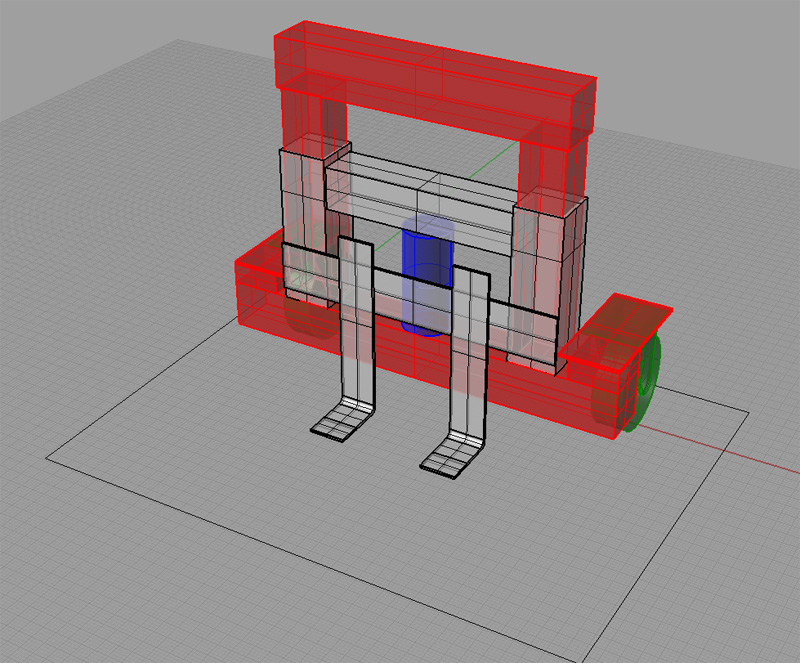

There were good elements to each, and I didn't want to pay what it costs for a pair of Rol-A-Lifts, so I decided to design and weld together my own version. Here is a rendering of what one dolly would look like with a Clausing-Kondia FV-1 milling machine:

In practice, we would use a dolly on either side of the mill, and would likely want to tie the two dollies together with some steel cross bars...

As the caption mentions, I would see using two dollies to move this machine, as well as using some steel cross bars at the top and bottom of the dolly to connect the two dollies together. I will need to think about how to connect them together in some variable length way that is rigid enough to hold well. Probably could use lengths of pipe or rod that is cross drilled for pins.

Casters, Jacks, and Raw Materials

In terms of store bought items, I needed a set of casters and a pair of bottle jacks as I intended to make 2 dollies. The casters I obtained from SurplusCenter for about half what MacMaster Carr wanted for something similar:

The casters are spec'd as:

This should be fine for my purposes if not overkill. I wanted large diameter casters because I had read in many places they will make rolling over cracks and debris a lot easier and that definitely describes how I'll be using these dollies!

For bottle jacks I intend to just mosey on over to Kragen and buy 2 cheap bottle jacks with a 4-6 ton capacity. Much more than that and I don't want to be messing with it anyway.

Dolly Plans

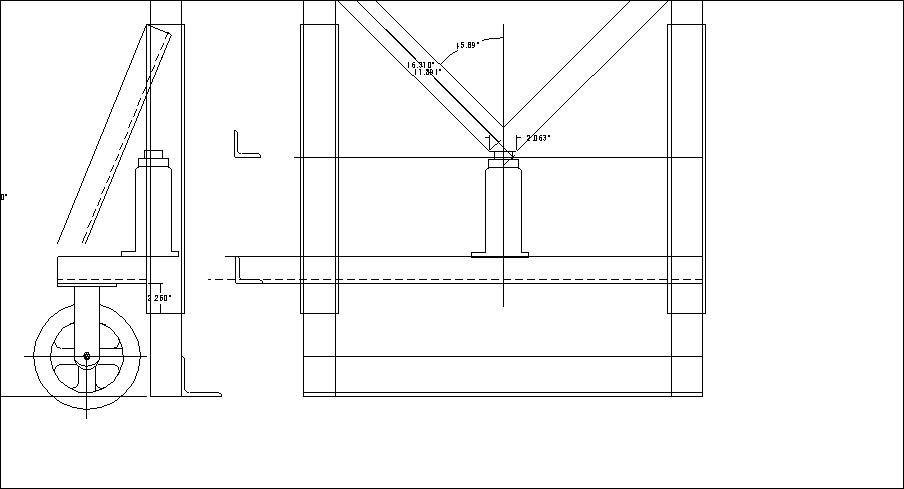

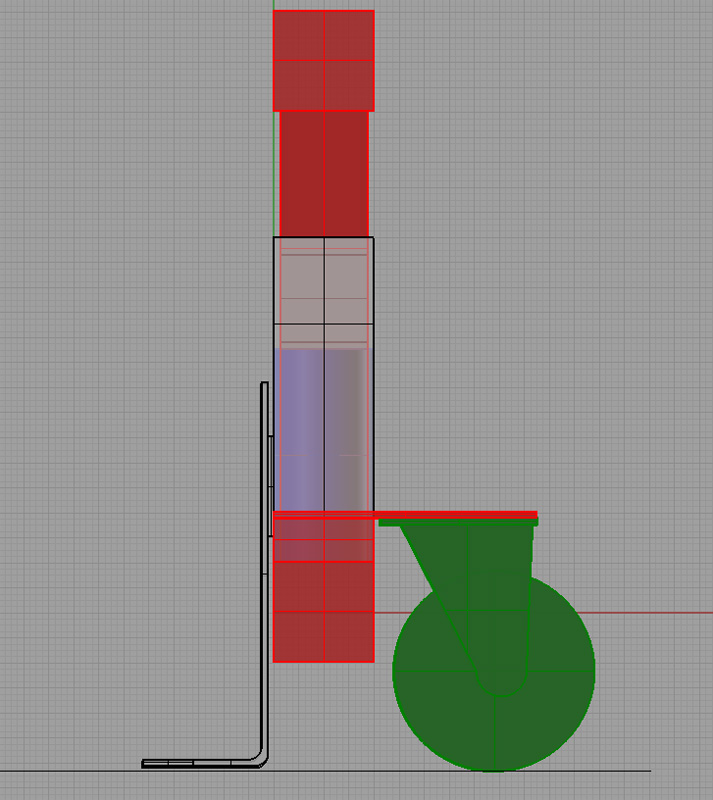

Here are the plans I came up with:

The forklifts ride on 3 1/2" square tubing rails. The forklift guides are 4" square tubing. Plates are 1/4" steel.

The unit will have 4" of ground clearance and a capacity to lift the forks up to 5".

|

Do you want to be a better CNC'er? Get Better Tool Life, Surface Finish, and Material Removal Rates.

|

||||||||||||||||||

| ||||||||||||||||||