Feeds and Speeds for Wood

CNC Feeds and Speeds Cookbook

Italian Olive by Cookwoods.com...

Here's your comprehensive guide to Feeds and Speeds for Wood, together with Tips and Techniques that are specific to cutting wood on a CNC Machine.

Wood Types

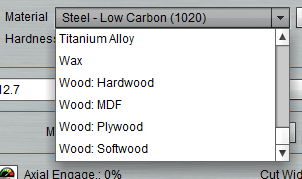

When calculating feeds and speeds for wood, we generally look at 4 different famillies. You can see them in our G-Wizard Feed and Speed Calculator's Material menu:

Just 4 wood types? Why not more?

To access the full variety of woods under each family, use the "More..." button on G-Wizard.

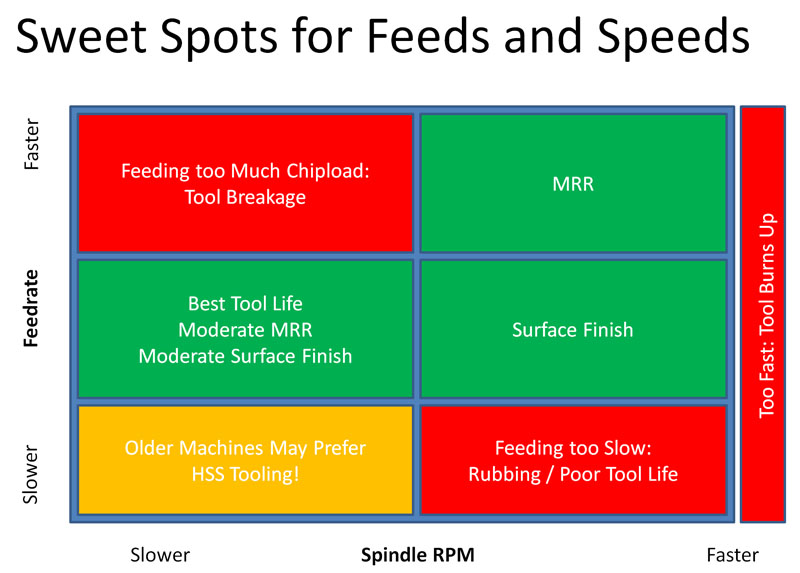

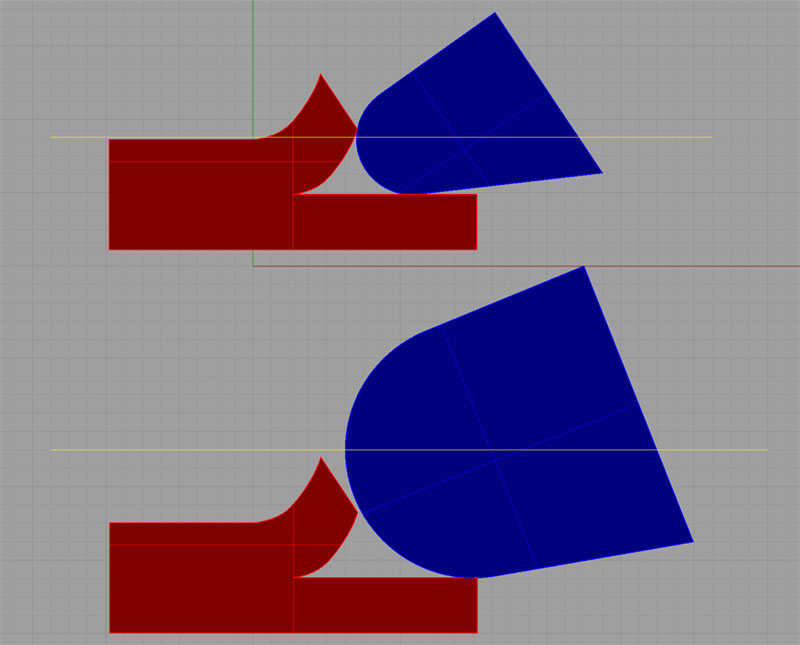

People wonder why we don’t have a lot more categories and sub-categories. After all, there are so many categories for steel, why not for wood too? The answer has to do with the size of the “sweet spot” that relates feeds and speeds to good results in a material, together with the relative hardness of the woods (or other materials) versus the cutters (HSS or Carbide). The Sweet Spot determines how the relationship between speed (spindle rpm) and feedrate need to come together for good cutting results. A typical Sweet Spot looks like this schematically:

The green areas reflect ideal Sweet Spot matches for a material and cutting conditions. You can optimize MRR (Material Removal Rate), Surface Finish, and to an extent a blend of all three. Red reflects danger zones. It’s important to note you can get into just as much trouble running too slowly (due to rubbing) as running too quickly.

Tools usually fail for a couple of main reasons:

– They get too hot, which softens the tool and results in a dull edge. Tools have a certain maximum speed, called the “Surface Speed” that governs how fast they can run against a given material. Running too slowly relative to feeds also generates a lot of heat due to Rubbing. This destroys a tool gradually, though gradual can mean a matter of minutes if the tool is hot enough.

– Tools can break because the flutes get too full, the chips have no place to go, and the tool jams and snaps off. This destroys a tool suddenly and is more commonly what beginners see.

A lot else can shorten a tools life–chipped edges in some materials, materials like stainless steel can “work harden” and suddenly become much harder during the cutting process, and some materials like aluminum try to weld themselves to the cutting edge if lubricant or appropriate tool coatings are not used. But, over heating and chip loading are the two main tool life enemies that are directly feeds and speeds related.

You can learn all this and much more from our free Feeds and Speeds Tutorial, but for now, let’s stay with this idea of a Sweet Spot. In general, the sweet spots for woods are much larger than for metals. For harder steels and difficult materials like Titanium, the sweet spot gets very small indeed. Imagine there are actual numbers on our Sweet Spot diagram. “Size” of Sweet Spot refers to how wide a range of numbers are safe.

What determines the “Size” of a Sweet Spot?

A lot of this is all up to that relative difference in hardness between material and cutter. Even Carbide is not all that much harder than hardened steel whereas it is phenomenally harder than even the hardest woods. Red Oak, for example, has a Brinell Hardness of about 3.7. Mild steel is 120, hardened steel is 900, and tungsten carbide is 4000!

It turns out that the characteristics that affect the feeds and speeds for wood are different than hardness. They have to do for example with the behavior of the sap relative to the sawdust and how the chips are made. Plastics, similarly, can behave differently–hard plastics as a name is a bit of a misnomer (though it is the industry standard in tooling catalogs). It refers to the chipping characteristics of the plastic. Hard Plastic turns to dust–it shatters. Soft Plastics allow a nice clean chip to be sliced off, almost like you slice cheese with a knife. Of course, the same is true for woods. “Hard” Wood versus “Soft” Wood has more to do with the seeds of the Wood than the actual hardness. Balsa seems soft but is technically a Hardwood. Hardwood seeds have a covering–shell or fruit, while Softwood does not.

Another factor influencing all this has to do with manufacturing process for the material. In the case of materials like MDF and Plywood, their manufacture can result in abrasive grit being embedded in the layers and that grit matters more than the wood in feeds and speeds. This is why so much router work prefers Carbide tooling even though wood is relatively soft. HSS just doesn’t stand up to that kind of grit very well.

With all that said, there are still differencs in hardness for various woods, and there is a standard scale, called the "Janka" scale that is used to rate the relative hardness of various woods.

Softwoods

Here are the various softwoods, sorted by Janka hardness, that one might attempt to CNC:

| Common Name |

Scientific Name |

Janka

Metric Hardness

K-N |

Janka

Imperial Hardness

lb-feet |

| balsa |

Ochroma pyramidale |

0.4 |

90 |

| ceiba |

Ceiba pentandra |

1.1 |

240 |

| cottonwood - balsam poplar |

Populus balsamifera |

1.3 |

300 |

| white-cedar, northern |

Thuja occidentalis |

1.4 |

320 |

| aspen, quaking |

Populus tremuloides |

1.6 |

350 |

| buckeye, yellow |

Aesculus octandra |

1.6 |

350 |

| cedar, atlantic white |

Chamaecyparis thyoides |

1.6 |

350 |

| cottonwood, black |

Populus trichocarpa |

1.6 |

350 |

| fir, subalpine |

Abies lasiocarpa |

1.6 |

350 |

| red cedar, western |

Thuja plicata |

1.6 |

350 |

| willow, black |

Salix nigra |

1.6 |

360 |

| cuangare |

Dialyanthera spp. |

1.7 |

380 |

| okoume |

Aucoumea klaineana |

1.7 |

380 |

| pine, eastern white |

Pinus strobus |

1.7 |

380 |

| pine, sugar |

Pinus lambertiana |

1.7 |

380 |

| jelutong |

Dyera costulata |

1.7 |

390 |

| spruce, Engelmann |

Picea engelmanni |

1.7 |

390 |

| fir, balsam |

Abies balsamea |

1.8 |

400 |

| basswood, American |

Tilia americana |

1.8 |

410 |

| basswood, Carolina |

Tilia caroliniana |

1.8 |

410 |

| fir, noble |

Abies procera |

1.8 |

410 |

| aspen, bigtooth |

Populus grandidentata |

1.9 |

420 |

| pine, western white |

Pinus monticola |

1.9 |

420 |

| redwood, second growth |

Sequoia sempervirens |

1.9 |

420 |

| sajo |

Campnosperma panamensis |

1.9 |

425 |

| cottonwood, eastern |

Populus deltoides |

1.9 |

430 |

| fir, pacific silver |

Abies amabilis |

1.9 |

430 |

| obeche |

Triplochiton scleroxylon |

1.9 |

430 |

| pine, limber |

Pinus flexilis |

1.9 |

430 |

| cypress, Mexican |

Cupressus lustianica |

2 |

460 |

| pine, ponderosa |

Pinus ponderosa |

2 |

460 |

| shorea, light red meranti |

Shorea spp., lauan-meranti group |

2 |

460 |

| incense-cedar |

Libocedrus decurrens |

2.1 |

470 |

| fir, white |

Abies concolor |

2.1 |

480 |

| pine, lodgepole |

Pinus contorta |

2.1 |

480 |

| redwood, old growth |

Sequoia sempervirens |

2.1 |

480 |

| spruce, white |

Picea glauca |

2.1 |

480 |

| chalviande |

Virola spp. |

2.1 |

481 |

| butternut |

Juglans cinerea |

2.2 |

490 |

| fir, grand |

Abies grandis |

2.2 |

490 |

| limba |

Terminalia superba |

2.2 |

490 |

| spruce, red |

Picea rubra |

2.2 |

490 |

| fir, California red |

Abies magnifica |

2.2 |

500 |

| hemlock, eastern |

Tsuga canadensis |

2.2 |

500 |

| pine, Jeffrey |

Pinus jeffreyi |

2.2 |

500 |

| banak |

Virola spp. |

2.3 |

510 |

| Douglas-fir, interior south |

Pseudotsuga menziesii |

2.3 |

510 |

| spruce, Sitka |

Picea sitchensis |

2.3 |

510 |

| tulapueta |

Osteophloeum platyspermum |

2.3 |

512 |

| spruce, black |

Picea mariana |

2.3 |

520 |

| chestnut, American |

Castenea dentata |

2.4 |

540 |

| hemlock, western |

Tsuga heterophylla |

2.4 |

540 |

| poplar |

Liriodendron tulipifera |

2.4 |

540 |

| yellow poplar |

Liriodendron tulipifera |

2.4 |

540 |

| catalpa, northern |

Catalpa speciosa |

2.4 |

550 |

| catalpa, southern |

Catalpa bignonioides |

2.4 |

550 |

| hura |

Hura crepitans |

2.4 |

550 |

| pine. red |

Pinus resinosa |

2.5 |

560 |

| baldcypress |

Taxcodium distichum |

2.3 |

570 |

| pine, jack |

Pinus banksiana |

2.5 |

570 |

| cedar, Alaska |

Chamaecyparis nootkatensis |

2.6 |

580 |

| cedar, yellow |

Cupressus nootkatensis |

2.6 |

580 |

| alder, red |

Alnus rubra |

2.6 |

590 |

| silverbell, Carolina |

Halesia carolina |

2.6 |

590 |

| tamarack |

Larix laricina |

2.6 |

590 |

| Douglas-fir, interior north |

Pseudotsuga menziesii |

2.7 |

600 |

| Spanish-cedar |

Cedrela spp. |

2.7 |

600 |

| ilomba |

Pycnanthus angolensis Exell |

2.7 |

610 |

| red cedar, southern |

Juniperus silicicola |

2.7 |

610 |

| pine, pitch |

Pinus rigida |

2.8 |

620 |

| cativo |

Prioria copaifera |

2.8 |

630 |

| sassafras |

Sassafras albidum |

2.8 |

630 |

| alder, European |

Alnus glutinosa |

2.9 |

650 |

| determa |

Ocotea rubra |

2.9 |

660 |

| Douglas-fir, interior west |

Pseudotsuga menziesii |

2.9 |

660 |

| pine, spruce |

Pinus glabra |

2.9 |

660 |

| pine, Table Mountain |

Pinus pungens |

2.9 |

660 |

| primavera |

Tabebula donnell-smithii |

2.9 |

660 |

| pulgande |

Dacryodes spp. |

3 |

666 |

| hemlock, mountain |

Tsuga mertensiana |

3 |

680 |

| sumac, staghorn |

Rhus typhina |

3 |

680 |

| pine, loblolly |

Pinus taeda |

3.1 |

690 |

| pine, shortleaf |

Pinus echinata |

3.1 |

690 |

| magnolia, cucumber tree |

Magnolia acuminata |

3.1 |

700 |

| maple, silver |

Acer saccharimum |

3.1 |

700 |

| Douglas-fir, coast |

Pseudotsuga menziesii |

3.2 |

710 |

| boxelder |

Acer negundo |

3.2 |

720 |

| cedar, Port Orford |

Chamaecyparis lawsoniana |

3.2 |

720 |

| chinkapin, giant |

Castanopsis chrysophylla |

3.2 |

730 |

| pine, sand |

Pinus clausa |

3.3 |

730 |

| pine, pond |

Pinus serotina |

3.3 |

740 |

| pine, virginia |

Pinus virginiana |

3.3 |

740 |

| birch, gray |

Betula populifolia |

3.4 |

760 |

| pine, slash |

Pinus elliotti |

3.4 |

760 |

| shorea, yellow meranti |

Shorea spp., lauan-meranti group |

3.4 |

770 |

| sycamore, american |

Platanus occidentalis |

3.4 |

770 |

| parana-pine |

Araucaria augustifolia |

3.5 |

780 |

| shorea, dark red meranti |

Shorea spp., lauan-meranti group |

3.5 |

780 |

| mahogany, true |

Swietenia macrophylla |

3.6 |

800 |

| magnolia, sweetbay |

Magnolia virginiana |

3.6 |

810 |

| tupelo, black |

Nyssa sylvatica |

3.6 |

810 |

| elm, american |

Ulmus americana |

3.7 |

830 |

| larch, western |

Larix occidentalis |

3.7 |

830 |

| mahogany, African |

Khaya spp. |

3.7 |

830 |

| elder, blue |

Sambucus cerulea |

3.7 |

840 |

| ash, black |

Fraxinus nigra |

3.8 |

850 |

| maple, bigleaf |

Acer macrophyllum |

3.8 |

850 |

| sweetgum |

Liquidambar styraciflua |

3.8 |

850 |

| elm, slippery |

Ulmus rubra |

3.8 |

860 |

| pine, pinyon |

Pinus edulis |

3.8 |

860 |

| pine, longleaf |

Pinus palustris |

3.9 |

870 |

| hackberry |

Celtis occidentalis |

3.9 |

880 |

| tupelo. water |

Nyssa aquatica |

3.9 |

880 |

| red cedar, eastern |

Juniperus virginiana |

4 |

900 |

| sande |

Brosimum spp., utile group |

4 |

900 |

| birch, paper |

Betula papyrifera |

4 |

910 |

| ekop |

Tetraberlinia tubmaniana |

4.1 |

910 |

| pine, ocote |

Pinus oocarpa |

4 |

910 |

| anime |

Protium spp. |

4.1 |

920 |

| sourwood |

Oxydendrum arboreum |

4.2 |

940 |

| cherry, black, American |

Prunus serotina |

4.2 |

950 |

| maple, red |

Acer rubrum |

4.2 |

950 |

| robe |

Tabebul spp., roble group |

4.3 |

960 |

| ash, pumpkin |

Fraxinus profunda |

4.4 |

990 |

Hardwoods

Here are the various hardwoods, sorted by Janka hardness, that one might attempt to CNC:

| Common Name |

Scientific Name |

Janka

Metric Hardness

K-N |

Janka

Imperial Hardness

lb-feet |

| teak |

Tectona grandis |

4.4 |

1000 |

| walnut, black |

Juglans nigra |

4.5 |

1010 |

| albarco |

Cariniana spp. |

4.5 |

1020 |

| holly, American |

Ilex opaca |

4.5 |

1020 |

| magnolia, southern |

Magnolia grandiflora |

4.5 |

1020 |

| buckthorn, cascara |

Rhamnus purshiana |

4.6 |

1040 |

| oak, southern red |

Quercus falcata |

4.7 |

1060 |

| avodire |

Turraeanthus africanus |

4.8 |

1080 |

| manni |

Symphonia globulifera |

5 |

1120 |

| andiroba |

Carapa guianensis |

5 |

1130 |

| oak, chestnut |

Quercus prinus |

5 |

1130 |

| shorea, white meranti |

Shorea javanica, lauan-meranti group |

5.7 |

1140 |

| cherry, wild, European |

Prunus avium |

5.1 |

1150 |

| santa maria |

Calophyllum brasiliense |

5.1 |

1150 |

| ash, oregon |

Fraxinus latifolia |

5.2 |

1160 |

| juniper, alligator |

Juniperus deppeana |

5.2 |

1160 |

| maple, black |

Acer nigrum |

5.2 |

1180 |

| oak, overcup |

Quercus lyrata |

5.3 |

1190 |

| oak, water |

Quercus nigra |

5.3 |

1190 |

| ash, green |

Fraxinus pennsylvanica |

5.3 |

1200 |

| oak, black |

Quercus velutina |

5.4 |

1210 |

| oak, laurel |

Quercus laurifolia |

5.4 |

1210 |

| pine, heart |

Pinus resinosa |

5.5 |

1225 |

| kapur |

Dryobalanops spp. |

5.5 |

1230 |

| oak, swamp chestnut |

Quercus michauxii |

5.5 |

1240 |

| pine, Caribbean |

Pinus caribaea |

5.5 |

1240 |

| birch, river |

Betula nigra |

5.6 |

1260 |

| birch, yellow |

Betula alleghaniensis |

5.6 |

1260 |

| iroko |

Chlorophora spp. |

5.6 |

1260 |

| keruing |

Dipterocarpus spp. |

5.6 |

1270 |

| laurel, California |

Umbellularia californica |

5.6 |

1270 |

| myrtlewood |

Umbellularia californica |

5.65 |

1270 |

| angelique |

Dicorynia guianensis |

5.7 |

1290 |

| mersawa |

Anisoptera spp. |

5.7 |

1290 |

| oak, northern red |

Quercus rubra |

5.7 |

1290 |

| oak, shumard |

Quercus shumardii |

5.8 |

1290 |

| beech, American |

Fagus grandifolia |

5.8 |

1300 |

| ramin |

Gonystylus bancanus |

5.8 |

1300 |

| alder, white |

Alnus rhombifolia |

5.9 |

1320 |

| ash, white |

Fraxinus americana |

5.9 |

1320 |

| elm, cedar |

Ulmus crassifolia |

5.9 |

1320 |

| elm, rock |

Ulmus thomasii |

5.9 |

1320 |

| ovangkol |

Guibourtia ehie |

5.9 |

1330 |

| oak, post |

Quercus stellata |

6 |

1360 |

| oak, white |

Quercus alba |

6 |

1360 |

| oak, bur |

Quercus macrocarpa |

6.1 |

1370 |

| cypress, Australian |

Callitris glaucophylla |

6 |

1375 |

| coffeetree, Kentucky |

Gymnocladus dioicus |

6,2 |

1390 |

| oak, scarlet |

Quercus coccinea |

6.2 |

1400 |

| sepetir |

Pseudosindora palustris |

6.3 |

1410 |

| tanoak |

Lithocarpus densiflorus |

6.3 |

1420 |

| maple, sugar (hard) |

Acer saccharum |

6.4 |

1450 |

| madrone, Pacific |

Arbutus menziesii |

6.5 |

1460 |

| oak, willow |

Quercus phellos |

6.5 |

1460 |

| birch, sweet |

Betula lenta |

6.5 |

1470 |

| oak, cherrybark |

Quercus falcata varpagodifolia |

6.6 |

1480 |

| hickory, bitternut |

Carya cordiformis |

6.7 |

1500 |

| merbau |

Intsia spp. |

6.7 |

1500 |

| pau marfim, Patagonian maple |

Balfourodendron riedelianum |

6.7 |

1500 |

| oak, pin |

Quercus palustris |

6.7 |

1510 |

| sapele |

Entandrophragma cylindricum |

6.7 |

1510 |

| witch hazel |

Hamamelis virginica |

6.8 |

1530 |

| elm, winged |

Ulmus alata |

6.8 |

1540 |

| hickory, water |

Carya aquatica |

6.9 |

1550 |

| afrormosia |

Pericopsis elata |

6.9 |

1560 |

| honeylocust |

Gleditsia triacanthos |

7 |

1580 |

| peroba de campos |

Paratecoma peroba |

7.1 |

1600 |

| yew, Pacific |

Taxus brevifolia |

7.1 |

1600 |

| oak, swamp white |

Quercus bicolor |

7.2 |

1620 |

| opepe |

Nauclea diderrichii |

7.3 |

1630 |

| alder, Nepalese |

Alnus nepalensis |

7.4 |

1690 |

| locust, black |

Robinia pseudoacacia |

7.6 |

1700 |

| pilon |

Hyeronima spp. |

7.6 |

1700 |

| kempas |

Koompassia malaccensis |

7.6 |

1710 |

| para-angelim |

Hymenolobium excelsum |

7.7 |

1720 |

| piquia |

Caryocar spp. |

7.7 |

1720 |

| apple |

Malus sylvestris |

7.7 |

1730 |

| peroba rosa |

Aspidosperma spp., peroba group |

7.7 |

1730 |

| tree-of-heaven |

Ailanthus altissima |

7.7 |

1731 |

| angelin |

Andira inermis |

7.8 |

1750 |

| benge |

Guibourtia arnoldiana |

7.8 |

1750 |

| hornbeam, American |

Carpinus caroliniana |

7.9 |

1780 |

| shorea |

Shorea spp., baulau group |

7.9 |

1780 |

| ebony, black and white, pale moon |

Diospyros malabarica |

7.9 |

1790 |

| laurel, mountain |

Kalmia latifolia |

8 |

1790 |

| serviceberry |

Amelanchier spp. |

8 |

1800 |

| hickory, shellbark |

Carya lacinosa |

8.1 |

1810 |

| hickory, pecan |

Carya illinoensis |

8.1 |

1820 |

| hophornbeam, eastern |

Ostrya virginiana |

8.3 |

1860 |

| purpleheart |

Peltogyne spp. |

8.3 |

1860 |

| hickory, shagbark |

Carya ovata |

8.4 |

1880 |

| jarrah |

Eucalyptus marginata |

8.5 |

1910 |

| wenge |

Millettia laurentii |

8.4 |

1930 |

| degame |

Calycophyllum candidissimum |

8.6 |

1940 |

| hickory. mockernut |

Carya tomentosa |

8.8 |

1970 |

| pedauk - African |

Pterocarpus soyauxii |

8.6 |

1970 |

| ash, blue |

Fraxinus quadrangulata |

9 |

2030 |

| karri |

Eucalyptus diversicolor |

9.1 |

2040 |

| wallaba |

Eperua spp. |

9.1 |

2040 |

| hickory, pignut |

Carya glabra |

9.5 |

2140 |

| sucupira |

Diplotropis purpurea |

9.5 |

2140 |

| dogwood, flowering |

Cornus florida |

9.6 |

2150 |

| goncalo alves |

Astronium graveolens |

9.6 |

2160 |

| mahogany, Santos, Cabreuva |

Myroxylon balsamum |

9.8 |

2200 |

| tornillo |

Cedrelinga cateniformis |

10.2 |

2299 |

| ebony, persimmon, white |

Diospyros virginiana |

10.2 |

2300 |

| mora |

Mora spp. |

10.2 |

2300 |

| persimmon, common |

Diospyros virginiana |

10.2 |

2300 |

| mesquite |

Prosopis spp. |

10.4 |

2345 |

| cherry, Brazilian |

Castenea dentata |

10.4 |

2350 |

| courbaril |

Hymenaea courbaril |

10.5 |

2350 |

| greenheart |

Chlorocardium rodiei |

10.5 |

2350 |

| ebony, Ceylon, East Indian |

Diospyros cebenum |

10.8 |

2430 |

| granadillo |

Platymiscium yucatanum |

10.9 |

2450 |

| oak, live |

Quercus virginiana |

12.9 |

2680 |

| bubinga |

Guibourtia spp. |

12 |

2690 |

| olive |

Olea europaea, O. capensis |

|

2700 |

| rosewood, Brazilian |

Dalbergia nigra |

12.1 |

2720 |

| sucupira |

Bowdichia brasiliensis |

12.2 |

2750 |

| osage orange, horse apple |

Maclura pomifera |

12.3 |

2760 |

| bloodwood, conduru, cardinal wood |

Brosimum rubescens |

14 |

2900 |

| kaneelhart |

Licaria spp. |

12.9 |

2900 |

| ebony, mun |

Diospyros mun |

13.4 |

3000 |

| macawood |

Platymiscium spp. |

14 |

3150 |

| rosewood, Indian |

Dalbergia latifolia |

14.1 |

3170 |

| bulletwood |

Manilkara bidentata |

14.2 |

3190 |

| ebony, African, Gaboon, Nigerian |

Diospyros crassiflora |

14.1 |

3220 |

| ebony, Macassar, striped |

Diospyros celebica |

14.1 |

3220 |

| azobe |

Lophira alata |

14.9 |

3350 |

| manbarklak |

Eschweilera spp. |

15.5 |

3480 |

| ipe |

Handroanthus spp. (lapacho group), Brazilian walnut |

15.6 |

3510 |

| marishballi |

Lincania spp. |

15.9 |

3570 |

| lignumvitae |

Guaiacum spp. |

20 |

4500 |

Tips and Techniques for Cutting Wood on a CNC Machine

Carbide or HSS Cutters?

In most cases, you'll want to purchase carbide cutters. First, a lot of wood products such as plywood and MDF can contain considerable amounts of highly abrasive grit due to the way they are manufactured. That grit radically shortens the life of HSS tools and you'll need carbide to stand up to it. Second, the spindle speeds used in most CNC woodwork are very fast, and this is also advantageous for Carbide because it tolerates the higher temperatures associated with the fast speeds better. Lastly, carbide is much stiffer than HSS, and so tool deflection is less likely to be a problem. Here is a great article: What Every CNCer Ought to Know About Tool Deflection.

Avoid Splintering the Surface with Special Router Bits

Specialize bits are available to help reduce the likelihood of splintering the surface of your wood (or laminated materials too):

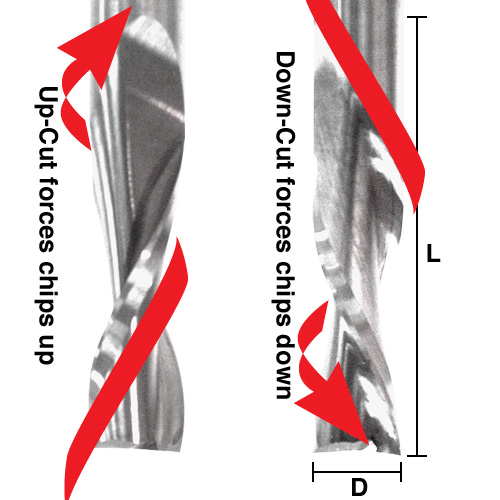

- Upcut: This is the normal end mill style. The spiral flute carries chips up and out of the hole as it cuts. These are probably the worst about splintering, though with serious fine tuning and slower feeds and speeds you may be able to tame it a bit.

- Downcut: With downcut geometry, the spiral is reversed so it pushes down instead of pulling up. This is great for reducing splintering of the top surface, but you do want to be careful the chips can go somewhere. Cutting deep tight slots can be problematic for this type of cutter sometimes.

- Compression: A compression cut is a combination of upcut and downcut. It has the spiral set to pull up at the bottom of the material, then it reverses direction at the top. It's name comes because it is pushing the chips to the center of the cutter, or "comrpessing" them, in other words. Compression cutters can avoid splintering both top and bottom, so are ideal for many applications where you're making one pass to cut all the way through the material.

- Straight Flute: Straight flutes have no twist. This reduces their likelihood of splintering, and it also makes the cutters cheaper. However, their performance is not so hot in terms of ultimate feeds and speeds.

For much more on Cutters for CNC Routers, see our specific article.

More Splintering and Tear-Out Tips

- The more porous the wood, the more likely it is to splinter.

- Slower, shallower cuts will reduce the splintering.

- Climb Cutting can make tear-out less like than Conventional Milling.

CNC Router or VMC?

Would you believe that for many CNC woodworking applications, a VMC (Vertical Machining Center) can make more sense than a CNC Router? All sorts of companies like Taylor Guitars and Fender are using VMC's on a daily basis for woodwork. That link has the details, but here are some of the reasons why:

- Cost: When high levels of precision are needed (guitar making is very precise), the VMC can achieve precision at a lower price point.

- Floor Space: Most of the gantries are set up to take 4×8 sheets. These custom shops are doing smaller runs and they’re not machining plywood sheets. The desire to include climate control to keep the wood stable also means shop floor square footage is at a premium. Smaller machine footprints help keep this cost under control.

- Dust Control: The full enclosure of a VMC really helps keep the dust down in the shop.

- Tool Changer: While they’re certainly available for CNC Routers, they’re standard on VMC’s. Fender needs 21 tools for their application and keeps 20 in the changer and the 21st sits in a dedicated space on the table where the spindle can fetch it as needed.

Vacuum Table Tips

Vacuum Tables are often the preferred method of workholding for wood, and we have a huge page chock full of great information on how to use Vacuum Tables.

Check out our Total Guide to Vacuum Tables...

Calculating Feeds and Speeds for Wood

Feeds and Speeds Calculator for Wood and CNC Routers

For CNC Woodworking applications, a good Feeds and Speeds Calculator needs the following features:

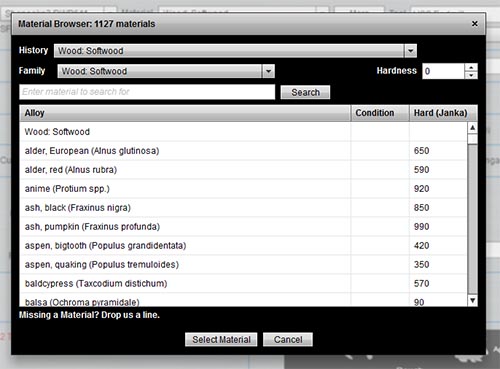

- A detailed wood database to fine tune Feeds and Speeds by wood species.

- Support for the special cutters used by CNC Routers such as downcut, compression, and straight flute.

- If you have a hobby-class machine, it isn't as sturdy or rigid as a commercial machine. Feeds and Speeds will need to be adjusted.

- Support to help you limit feeds and speeds to levels that won't pop the parts of your vacuum table.

Our G-Wizard Calculator is the world's first feeds and speeds calculator specifically designed for CNC Router use, and it does all that and more.

G-Wizard's Material Database has hundreds of wood species built-in...

My Cutter Gets Really Hot or the Wood is Being Burnt

If the cutter is getting hot to the touch (careful!), and especially if there is any discoloration or the wood is being burnt, your feedrate relative to the proper feedrate is too slow, and the cutter is rubbing. For a full explanation of rubbing, see this article from our Feeds and Speeds Tutorials.

Geometry causes rubbing when we feed cutters too slowly. It heats everything up and will burn wood...

More CNC Wood Resources

Machining Wood in a Vertical Machining Center

CNC Machining Fuels Guitar Innovations

They Build Dreams: The Fender Custom Shop

Onsrud CNC Production Routing Guide

How to Survive Your First CNC Router Fire

Lumber Size Information

Try the Free Trial Version of G-Wizard Speeds and Feeds Calculator...

No credit card required--just your name and email.