|

Want to be a better CNC'er? Get our weekly newsletter plus a package of greatest hits, special tips, and more, all for free. I'm Ready to Be a Better CNC'er, Hook Me Up! |

Ballscrew Bearing Blocks and Ballscrew Machining

Lathemaster 9x30 Lathe Conversion: Z-axis

For the Lathemaster, I'm going to use Rockford 0.631" diameter precision rolled ballscrew for the Z axis. Cost for 30" is $65, which includes an allowance for annealing both ends so it'll be easy to machine. A pair of ballnuts (so I can preload) with wipers is another $122, for a total cost of $187. My IH CNC mill uses Rockford ballscrews and I'm very happy with their quality.

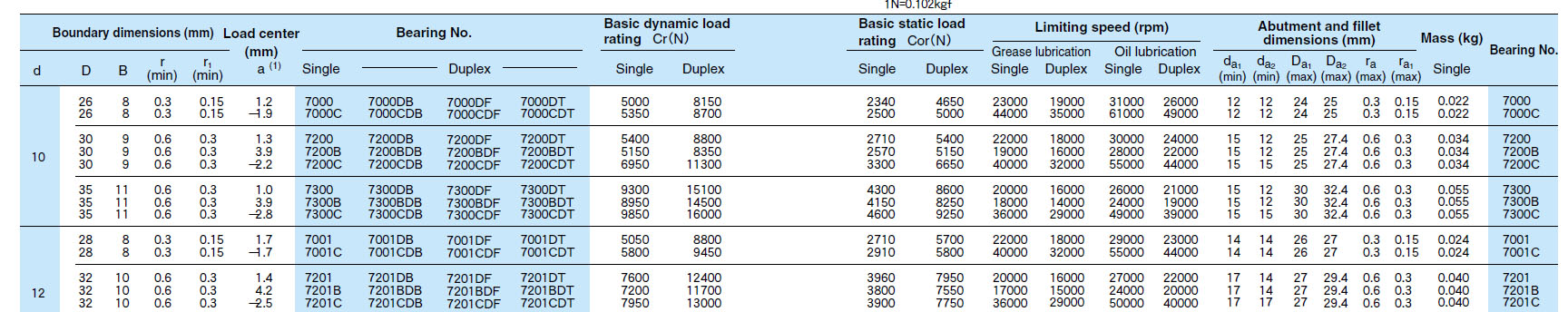

VXB offers high quality Nachi angular contact bearings and we can peruse the Nachi literature for an appropriate bearing:

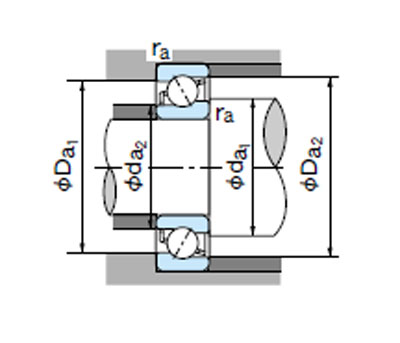

We want a bearing such that the ballscrew outer diameter matches up well with the da1 value. In this case, our 0.631" ballscrew has an outer diameter of a little over 16mm, so we can use a 7200 bearing for the job, since it takes a 15mm OD. Those bearings are only $9.16 for Nachi's, but I think the pair of no-name 7200B's for the same price from VXB should be adequate.

From this data, we can see that the shaft that passes through the bearing will need to be 10mm (0.3937") in diameter, and the nut that we use to secure the end of the ballscrew against the bearing inner race will be 12mm (0.4724") in diameter, or perhaps slightly larger. The ballscrew shoulder should be 15mm (0.5906") in diameter.

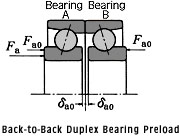

We want to install these bearings in a back-to-back configuration with preload. If they were matched duplex bearings, their designation would be 7200BDB. According to NSK, a medium to heavy preload would be 59 to 127 Newtons. Preload is achieved via spacer or springs positioned to move the inner races apart like so:

In order to use springs, we would need to have wavy (Bellville) springs with an ID to fit the shaft (10mm or 0.3937") and an OD about the same as the nut we will use (15mm or 0.5906"). McMaster Carr has ball bearing springs that are perfectly sized to the job and deliver 51N per spring. A pair of such springs should do the job. If we torque that lock nut down until it can't move and then back off slightly, we will ensure our springs are delivering the proper preload.

|

Do you want to be a better CNC'er? Get Better Tool Life, Surface Finish, and Material Removal Rates.

|

||||||||||||||||||

| ||||||||||||||||||